Pulp&Paper Innovation that

adds Values to our lives.

connecting to our vision of paper’s future

When Moorim makes paper, it is making the planet greener.

Moorim uses wood from sustainably harvested forests to make the pulp and

uses the energy generated in the process to make paper in a smart way.

Moorim Environmental Management Strategy and conducts three environment policies with response for climate change, development and management of eco-friendly products, and operating eco-friendly systems. Moorim conducts eco-friendly policies in accordance with ‘Low carbon and Green growth’ policy of governments. Moorim will provide customers with accurate information with clear eco-friendly management.

| ECO-friendly Global Pulp & Paper Company | |||

|---|---|---|---|

| Strategic Direction |

Cope with climate change

|

Development and Management of Eco-Friendly Products

|

Operation of Green Workplace

|

| Strategy Goals |

|

|

|

| ECO-friendly Global Pulp & Paper Company | |||

|---|---|---|---|

|

|||

|

|||

|

|||

- 1 We conduct continuous improvement activities through the establishment of an efficient environmental management system and periodic monitoring.

- 2We document our environmental policies for efficient management of environmental performance and implement our environmental management implementation plan by establishing environmental goals and objectives.

- 3We provide stakeholders with free access to the environmental policy and ensure transparency of environmental management through the achievement and certification of the environmental policy.

- 4 We provide systematic environmental education to all employees to raise environmental awareness and contribute to society through environmental conservation activities with a global perspective.

- 5 We make 3R (reduce, reuse, and recycle) a way of life to minimize environmental pollutant emissions and use resources and energy efficiently.

- 6 All staff shall sincerely and actively fulfill their roles and responsibilities to maximize the effectiveness of the environmental management system.

- 7We strongly embrace and comply with environmental laws and regulations and other requirements for environmental stewardship.

- 8 The management agent shall be responsible and authorized for the operation and maintenance of the environmental management system in accordance with this environmental policy and the requirements of ISO 14004.

We are also laying the foundation for minimizing environmental pollution from the pulp and paper process and establishing an environmentally friendly management system.

We have established a legitimate environmental policy and encourage all executives and employees to make it a priority.

Having obtained and maintained ISO 14001 certification, an international standard for the environmental management system, Moorim is committed to minimizing the negative environmental impacts that may arise in the course of business and to promoting efficient resource consumption and regeneration.

-

01

Planning

Establish environmental management manuals and goals -

02

Implementation and Operation

Operate and manage environmental management program -

03

Inspection

Evaluate and monitor performance -

04

Management Review

Review environmental systems and reflect into environmental management

Moorim recognizes the importance of biodiversity for sustainable development and environmental protection.

We are committed to preserving biodiversity and minimizing its impact.

-

Recognition of biodiversity importance

-

Development of biodiversity-friendly products

-

Biodiversity protection activity

-

Supporting interested party’s biodiversity protection activity

| Strategic Direction | Establishment and Implementation of a Net-Zero strategy | Management of Scope 3 Emissions | Expansion of Participation in Voluntary Initiatives |

|---|---|---|---|

| Strategic Goals |

|

|

|

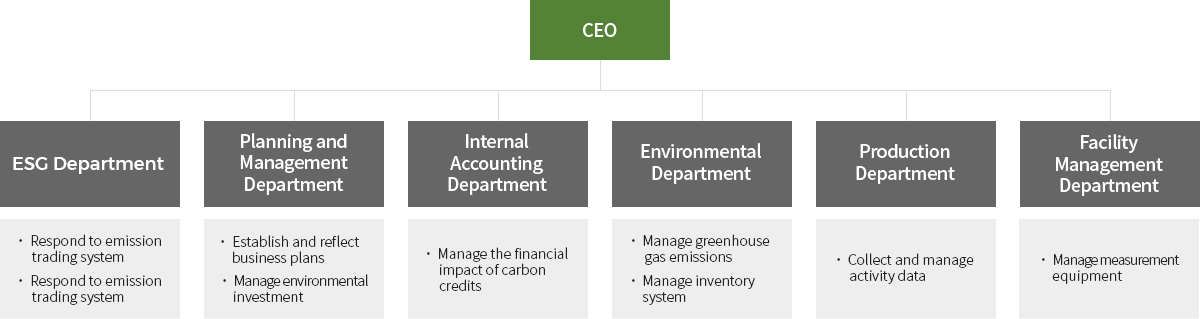

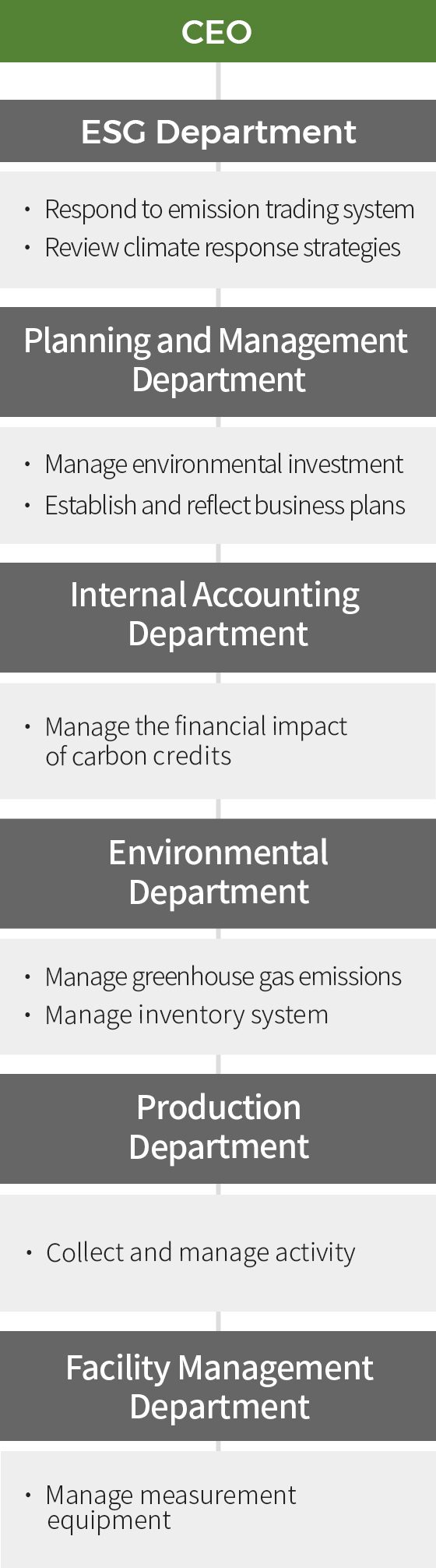

Moorim has established a company-wide organizational system to minimize the impact of climate change. We are making various efforts to preemptively respond to laws and regulations through a dedicated organization, review climate factors when establishing business direction and investing in large-scale facilities, manage the financial impact of carbon credits, and systematically manage emissions through an inventory system.

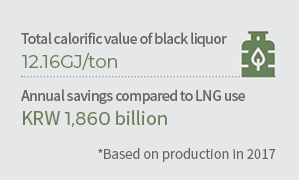

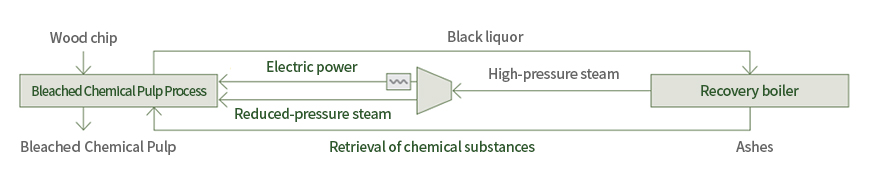

The ‘black liquor,’ a mixture of lignin and other extracts left over from pulp production process, becomes a biomass fuel. Moorim burns the black liquor in a recovery boiler to produce steam and electrical energy, and the remaining ash is recycled into chemicals needed for pulp production through a chemical recovery process, contributing to environmental protection and reducing carbon emissions.

Greenhouse Gas Raduction Effect of Black Liquor

Black Liquor Heat Recovery Process

- Investigate frequently used synthetic resin products

- Review the potential for paper substitution and quality security

- Design eco-friendly product by considering the product’s life cycle

- ncrease the percentage of recycled content

- Develop biodegradable products

- Expand acquisition of domestic and international environmental certifications

- Review new green certification acquisitions

- Collaborate with cosmetics and food companies to create customized products

- Plan promotions for eco-friendly products, such as branding and competitions

| Certificates | Certification Marks | Certification Details |

|---|---|---|

| FSC® |  |

Moorim Paper, Moorim SP and Moorim P&P have all acquired FSC® - CoC(Forest Stewardship Council®- Chain of Custody), FSC® - FM(Forest Management) certifications. We are equipped with the system to produce more responsible forestry FSC® certified products.

|

| PEFC™ |  |

Moorim acquired PEFC certification that promotes sustainable forest management and produces forest-friendly products.

|

| KFCC™ |  |

Moorim produce products using raw materials sourced from sustainably managed forests, recycled materials, and controlled materials

|

| Low Carbon Products |  |

In 2013, Moorim P&P acquired the first low-carbon product certification in the domestic paper industry, contributing to reducing greenhouse gases and preventing global warming. |

| Korea Eco-Label |  |

Moorim Paper acquired a Korea Eco-Label from the Environmental Industry and Technology, by incorporating 10~30% of waste paper into their product grades, resulting in resource conservation and pollution reductions. |

| Carbon Footprint |  |

Moorim Paper and Moorim SP acquired Carbon Footprint certifications for the Neostar Shopping bag and Neo Vote paper. |

| OK compost |  |

In March 2020, Moorim Paper and Moorim SP acquired the Biodegradability certification (OK Compost)’ issued Europe’s leading testing institute, TUV Austria. |

| OK biobased |  |

Moorim P&P acquired OK biobased certification for the CellRim® CP-130 |

| PREPS |  |

Moorim Paper and Moorim P&P received ratings on PREPS (Publisher’s Database for Responsible Environmental Paper Sourcing) from the British Printing Industries Federation. PREPS identifies the source of pulp materials for paper products and provides a list of paper products, allowing member companies to make their selections |

| Recyclability Certification(UL 2485/PTS) |  |

Moorim Paper and Moorim SP have passed both rigorous eco-friendly tests by the U.S. (UL) and European Testing Institutes (PTS) to obtain the recyclability certification. Unlike traditional PE coatings, Moorim’s is environmentally friendly and safe. |

- Moorim has expanded line of eco-friendly products such as NEO STAR GLOSS, NEO STAR UNCOATED PAPER, NEO STAR LABEL minimizing emission of pollutants

- Moorim Paper acquired FSC-CoC Certification first in korea in 2007 and later, Moorim SP, Moorim P&P also acquired FSC-CoC Certification

- Moorim was awarded by the Minister of Environment. Because line of art paper had been chosen as Green Product that reduces energy consumption and minimizes emission of pollutants

-

Smokeless mill

Moorim Paper

-

Equipment for preventing stink

Moorim Paper

-

Equipment for recycling waste water

Moorim SP

-

Equipment for collecting dust efficiently

Moorim P&P

Moorim actively invests in air pollution prevention facilities to minimize the environmental impact of pollutants and continuously checks emission levels to ensure compliance with air pollutant emission permit standards.

-

- Prevent air pollution by supplying steam through a cogeneration plant

-

- Minimize air pollution by using LNG, clean fuel

-

- Install and operate high efficiency equipment for collecting dust and advanced equipment for preventing air pollution

Moorim uses physical, chemical, and biological methods to remove pollutants and strives to minimize the impact on the water ecosystem around the site by expanding recycling to minimize water usage and wastewater discharge.

Filter waste water before emitting and recycle waste water. Recycle finally treated water into process water

- 1 st

Physical and chemical treatment - 2 nd

Microorganism treatment - 3 rd

Physical and chemical treatment

After third step purifications, recycle used water through Bag Filter

- 1 st

Physical and chemical precipitation method - 2 nd

Standard activated sludgy method - 3 rd

Sand Filter method

Recycle pulp sealing water which used in process, condensed water, and white water in dry process

- 1 st

Chemical and cohere treatment - 2 nd

Microorganism treatment - 3 rd

Chemical and cohere treatment

- MOORIM continuously reduces fan noise in the production press, emission noises, and transformer noises allowing nearby factories tolerable by reducing and elimination stink resources.

- The integrated mill minimizes noise by sound proofing. The Jinju mill, installation and operates an environment system which seals and collects stink in waste water treatment equipment and treat stink biologically.

Moorim manages waste generated in the course of business operations by categorizing it into general waste and designated waste and reliably disposes of waste through legitimate contractors. Every year, Moorim carries out activities to reduce the amount of waste generated and expand recycling processes to recycle waste.

- Recycle sludgy things which are emitted in process as earthworm feed etc.

- Minimize waste by improvement of process and introducing high efficient spin-dryer.

- Research and development of substitute for raw material, toxic substance.

Moorim complies with the standards for handling, storing, and keeping hazardous chemicals in accordance with relevant laws and operates facilities that meet the standards. In addition, chemicals used in the workplace are imported after prior approval of the hazardousness of the chemicals by the Environment and Safety Management Department in accordance with the internal chemical management process.

[Hazardous Chemical Management Process]

-

STEP 1

Pre-screening of chemicals -

STEP 2

Review of documentation related to chemicals -

STEP 3

Review of legal, regulatory, and internal control standards -

STEP 4

Review of allowance of chemicals into the premises