Pulp&Paper Innovation that

adds Values to our lives.

connecting to our vision of paper’s future

Since its inception, Moorim has put the safety and health of its members first.

Based on the philosophy of management,‘the workplace is a second home,’

we will create a happy workplace where all executives, employees,

and our partners can come together and be free from accidents and disasters.

-

Safety first

Moorim considers safety and hygiene, as well as related activities, as an utmost priority.

-

People-oriented

Moorim seeks to establish a safety system that covers not only its own employees but also the employees of partner companies.

-

Site-specific

Moorim seeks safe management with a focus on each site through strict supervision and thorough improvement activities based on systematic safety management.

-

Autonomous safety

Through continued safety and technical training, as well as prevention activities, Moorim will boost the awareness of safety management and establish an autonomous safety and hygiene system.

-

Responsible management

To create a safe workplace with no accidents or disasters and promote the health of its members, Moorim will provide optimal resources and live up to its responsibilities regarding safety and hygiene.

In July 2020, the executives and employees of Moorim laid a strong will to establish and realize ethical

management through proclamation of ethical management.

Moorim believes that the foundation of sustainable growth for future is the sense of ethics and fairness.

We will position ourselves as a corporation trusted by customers, a corporation that market needs,

and a corporation respected by the society by raising competitiveness through transparent management

innovation and social contributions.

Achievement of

zero accidents

and zero disasters

- Observation of 12 PSM action plans

- Strengthened safety management at partner companies

- Establishment of a site-led risk assessment culture

Prevention of

safety incidents

- Ongoing identification of potential risk factors on company premises

- Establishment of a site-led accident contingency plan

- Reinforced safety management for enclosed spaces

Establishment of a safety

culture among employees

- Institution of pre-work TPM activities

- Qualitative improvement of safety education

- Safety culture campaigns

- Regular health checkups for employees

-

Observation of PSM operation

- Regular PSM meetings (at least monthly)

- Implementation of 12 PSM initiatives

- PSM specialization training PSM : Process Safety Management

-

Safety /hygiene education

- Provide statutory health and safety training for all employees

- Provide statutory supervisor training

- Provide external expert training

- Provide statutory training for fire/ hazardous material safety managers

-

Safety management at partner companies

- Operate safety and health symbiotic cooperation program

- Support regular safety and health training for partners

- Host and activate safety and health consultative group with partners

- Joint inspections and walk-around inspections with partners

-

Contingency training

- Contingency training for each scenario (at least quarterly)

- Conduct public-private fire response drills

-

Prevention of safety incidents

- Safety Work Permit System Management

- Implement voluntary labor-management safety and health inspections

- Regular site safety and health patrol and inspection

- Conduct regular/irregular risk evaluation

- Discovery of Latent Risks

-

Corporate-wide council on safe management

- Implement a company-wide safety and health management working group

- Share and respond to major key workplace safety and health issues

ISO 45001 certification ensures the systematic management of safety and hygiene of the organizational members and contribution to corporate profits by forecasting and preventing any risks to safety or hygiene that may occur on business sites. Moorim Paper was certified on August 29, 2020

ISO 45001 certification ensures the systematic management of safety and hygiene of the organizational members and contribution to corporate profits by forecasting and preventing any risks to safety or hygiene that may occur on business sites. MOORIM SP was certified on October 14, 2020.

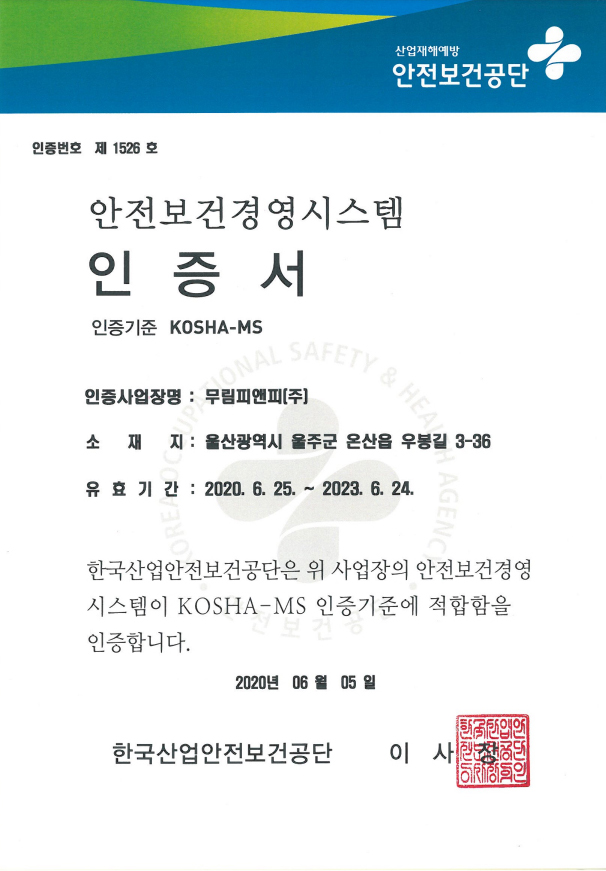

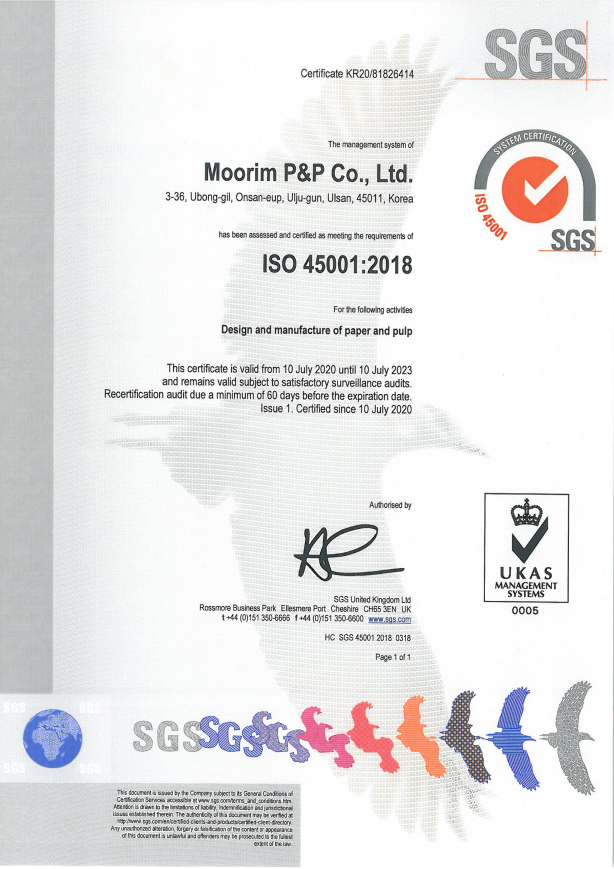

ISO 45001 certification ensures the systematic management of safety and hygiene of the organizational members and contribution to corporate profits by forecasting and preventing any risks to safety or hygiene that may occur on business sites. MOORIM P&P was certified on July 10, 2020.